Why Internal Hard Rubber Lining is needed?

An Epoch-Making Seawater Resistant Valve

|

|

We succeeded in providing a lining even for a shaft, which had been deemed impossible in the past, by interlocking a disc and a stem in our own unique way. As a result, there is no exposed stainless steel part inside the valve any more, thus eliminating the problem of galvanic battery corrosion that occurs between cast iron and stainless steel.

Disc and Stem rubber lined in our own unique way

Why Full Rubber Lining is Needed?

|

This picture shows the Disc of a swing check valve that has been corroded by seawater. The valving element is made from FC200 and the valve seat is manufactured from SUS304. FC200 is coated with epoxy powder. The valve made of SUS304 shows no corrosion at all, whereas the valving element of FC200 is simply corroded. Why? |

The mechanisim of corrosion

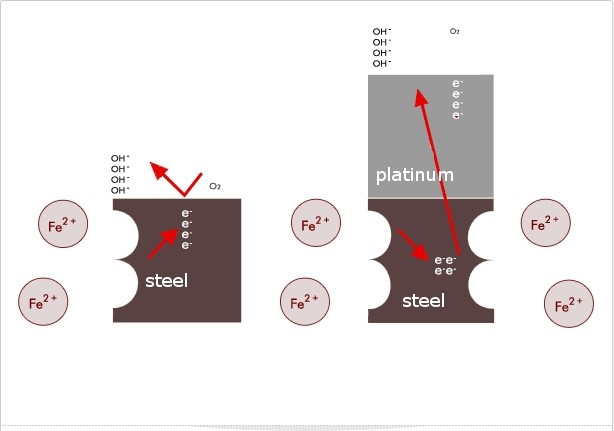

The diagram on the above depicts the mechanism of corrosion that is accelerated when 2 metals of dissimilar electric potentials contact each other. Diagram (a) shows when an oxygen molecule has diffused onto steel, 2 iron atoms dissolve. As shown on diagram (b), however, when another oxygen molecule has diffused onto platinum, 2 more iron atoms dissolve. It means that the rate of corrosion development doubles. This phenomenon is referred to as galvanic corrosion.”

It is not enough for protecting base metal that lining and coating on the base metal (for example, tar epoxy coating, tar epoxy resin coating and nylon coating etc) . Valve works so happens potential difference because of breaking away by working and the space between each parts and pinhole etc…

In other words, where there is a galvanic corrosion environment, it allows galvanic corrosion to take place. In addition, what is worse is that the area of stainless steel, noble metal, exposed to seawater is far greater than that of carbon steel, base metal, from which coating or lining peeled off.

Based on the belief that the problem of corrosion in valves can be resolved if we can eliminate the root cause, we finally succeeded in developing a novel method –an innovation to provide a lining for the entire stainless steel surfaces that are subject to corrosion by seawater. That is the valve free from galvanic battery corrosion.